|

Weifang henglian cellophane Co., Ltd

|

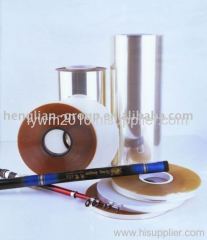

cellophane paper

| Price: | 3.5~4.5 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Excellence of gloss and transparency

2. Excellence of tensile strength, tensibility and twist stability

3. High adaptability in printing

1. 2. 3. 4. 6Aluminium-plating Cellophane

1.High adaptability in pringting and laminating.

2.Uitraviolet ray and gas proof and endurance of high temperature.High resistance and anti-penetrantion of chemical,grease and bacteria.

3.Excellent elongation rate,tensibility and property of tearing,the twisting stability is much better than PT -cellophane.

4.Aluminium-plating MST-cellophane is hea-sealing and moisture-proof.

5.High resistance and anti-penetration of chemical ,grease and bacteria.

6.Roll width:500-1,500mm

7.Substance:30-50g/m2

8.Main Applications:It is a new green packing material which aggregates the excellences of cellophane and Aluminium foil together.it's nonpoisonous,tasteless and superior to other packing materials.It'sthe first-chosen green-material for packing the foodstuff,medicine and cosmetic.

Special Cellophane for Fishing Rod and cellophane for Adhensive Tape

This kind of cellophane,with substance range of 45g-60g/m2 is made by special treatment during production,for special use of producing fishing rod and tape.Its characteristic is of high elongation,high tensile strength and excellent processing properties.Its resistance to high temperature and easy release from the mould made it special and unsubsitutive.

Color Cellophane

With the same specifications as the sheet or roll cellophane is available in even and delightful dyeing of red,green,yellow,orange and any other color designated by the buyer

MST-coated cellophane

MST-cellophane with substance range of 28g-60g/m2 is made by applying a thin layer of nitrocellulose laquer on the surface on the surface of PT-cellophane,which gives the film the important properties of moisture proofness and heat sealability,the barrier function to various gases,the excellent function for printing and laminationg.it is suitable for automatic high-speed packing and can significantly increase packing and decorating material for medicines,foodstuff,tea,cigarettes and tobacco,etc.

Roll Cellophane for printing and laminating

Roll cellophane for printing and laminating. Besides the basic properties of

PT-cellophane in sheet, the most important properties of the latter kind of roll

cellophane are that its thickness is much more even than sheet cellophane along

the whole width direction because of the little difference between the max.

thickness and the min. thickness of the film; and that it is more suitable for

printing and laminating because of the special surfact treated by special

processes.

PT-cellophane in sheet, the most important properties of the latter kind of roll

cellophane are that its thickness is much more even than sheet cellophane along

the whole width direction because of the little difference between the max.

thickness and the min. thickness of the film; and that it is more suitable for

printing and laminating because of the special surfact treated by special

processes.

PT-cellophane

PT-cellophane, with substance range of 20gsm~60gsm, is derived from wood pulp,

a natural fibrous from of cellulose, by the process of alkalization, xanthation

and casting. For this reason, PT-cellophane film is a kind of superior packing

and decoration material for foodstuff, medicines, tea, battery, cigarettes and

tobacco, etc.

packaging details:

inside packaging: wrapped with al-foil PE film , then with kraft paper. Outside packaging: veneer case with the labels on it OEM available .

packaging 3 "core roll, usually length from 2000m-5000m. . packaging: 6 or 9 finished rolls per pallet, core plugs to be used on each end . protective corrugated board to be used on top secured with plastic wrap on top and sides . iron straps to be used to secure entire assembly to pallet. .

PE, craft case for sheet cellophane , pallet for roll cellophane , well protect the goods.

STANDARD EXPORT PACKING

PE, al-foil, craft paper, wooden case, carton.

1> machine width: 1650-1800m size: 450mm \600mm\550mm in rolls and so on. Length: 2500-5000m.

2> sheet size: 1000*900, 500*750, 1000*750, 20*30, 30*40, 450*1000 and so on.

Roll: can be cut into different sizes even 10mm width.. / cellophane with all kinds of sizes even 10mm width.

Without deforming under 190℃.

3> MOQ: 5ton/tons , 3ton/tons

4> Delivery time : within 30 days on receipt of customers' 30% prepayment./ in 30 days after receiving the deposit.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!